Barrier Washer

Tecnologia all'avanguardia che apre la strada all'era del lavaggio intelligente

Specifically designed for the strict requirements of cleanroom operations, this washer-extractor is built with a dual-compartment isolation system that keeps clean and soiled areas completely separate. Tailored for cleanroom laundry processes, it ensures dependable hygiene for items such as anti-static garments, sterile gloves, and lint-free wipes.

In addition to cleanroom use, the machine is equally effective in managing heavily contaminated or pathogen-sensitive textiles, including hospital bedding, surgical attire, and infectious ward linens, providing a high level of protection and sanitation.

Capacità disponibili

Caratteristiche tecniche

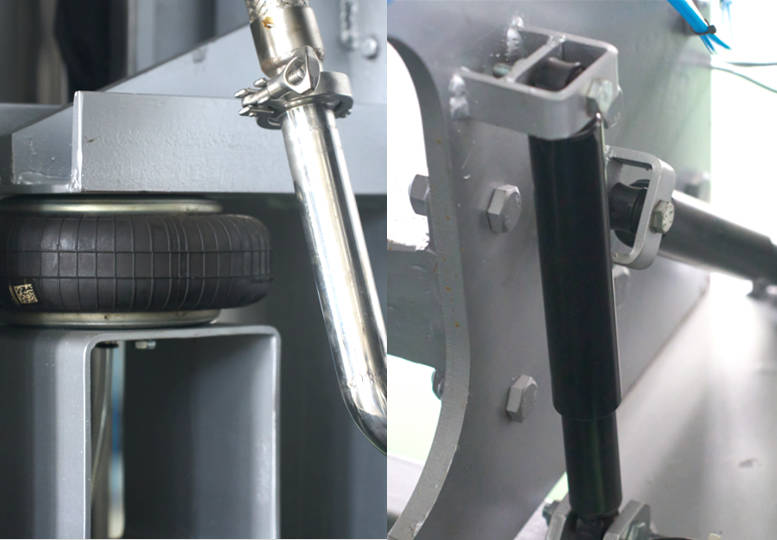

Shock Absorption Design

The machine adopts an underhung shock absorption structure. Equipped with German-imported air springs and hydraulic dampers, it operates with low vibration and low noise,making it suitable for cleanroom environments.

Detergent Dispensing Design

Utilizes peristaltic pumps to automatically dispense liquid detergents with high precision.

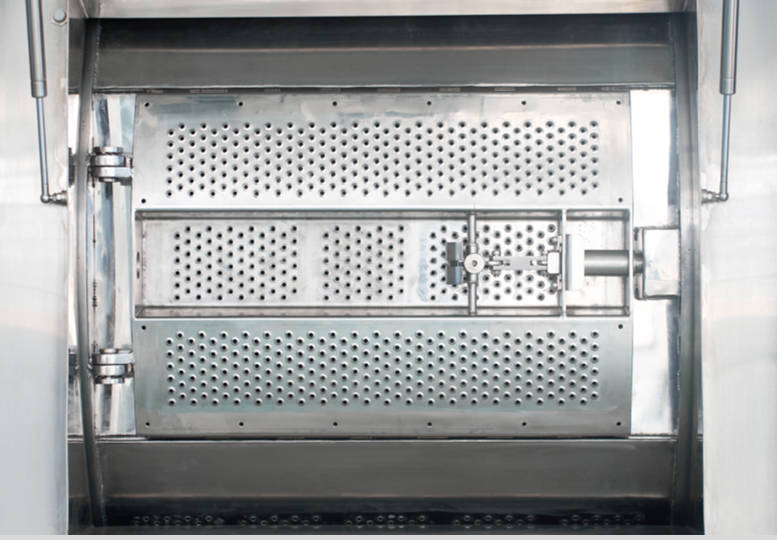

Safety Door Lock Design

The door is made of 304 stainless steel and equipped with a safety lock and interlock control system. This system provides reliable safety protection: the door cannot be opened while the machine is running, and the machine cannot start if the door is not properly closed. Additionally, when one side door is open, the other side remains locked to ensure isolation.

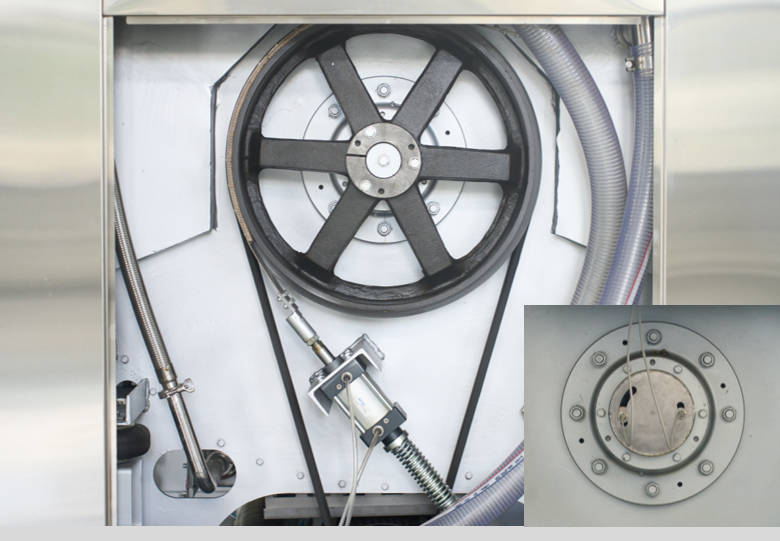

Stable, Efficient, and Long Service Life Design

The washing drum is horizontally mounted and supported by double-side bearings, ensuring smooth operation and high dewatering performance. The overall machine is designed for a long service life.

40 Wash Programs

Equipped with a full-color LCD touchscreen, the system features a menu-based interface and human-machine interaction mode with three-level user access. It supports up to 40 customizable wash programs. A programmable logic controller (PLC) is standard for pharmaceutical industry users.

Dual-Door Design (Front and Rear)

The front and unloading from the rear. When installed through a partition wall, it effectively separates the washing area (soiled side) from the finishing area (clean side). Loading and maintenance are performed in the washing area, while unloading and packaging are done in the finishing area, effectively preventing cross-contamination.

304 Stainless Steel Construction

All components that come into contact with water—such as the inner drum, outer tub, outer door, inlet valve, drain valve, and heating elements—are made of high-quality 304 stainless steel. This provides excellent resistance to acids and alkalis, superior corrosion protection, and prevents metal rust.

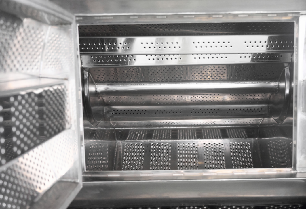

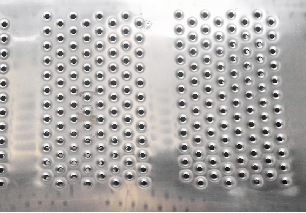

Recessed Drum Design

The washing drum features a recessed-hole design that undergoes both manual grinding and electrolytic polishing, ensuring a smooth surface that won’t snag fabrics. A unique anti-leak baffle structure effectively prevents small items (such as lint-free wipes) from escaping during operation.

Parametri tecnici

| Modle | N2050 | N2070 | N2100 |

|---|---|---|---|

|

|

|

|

| Water Consumption (L/cycle) | 650 | 860 | 1150 |

| Compressed Air Consumption (m³/h) | 0.15 | 0.15 | 0.15 |

| Compressed Air Pipe Diameter (mm) | Φ8 | Φ8 | Φ8 |

| Compressed Air Pressure (MPa) | 0.5 | 0.6 | 0.6 |

| Steam Consumption (Kg/h) | 50 | 70 | 100 |

| Water Inlet | DN25 | DN40 | DN40 |

| Steam Inlet | DN25 | DN25 | DN25 |

| Drain Outlet | DN63 | DN100 | DN100 |

| Recommended Capacity (Kg) | 50 | 70 | 100 |

| Power (kW) | 5.5 | 7.5 | 11 |

| Inner Drum Size (mm) | 1064×570×506 | 1064×830×730 | 1220×860×1005 |

| External Dimensions (mm) | 1390×1500×2140 | 1610×1500×2140 | 1720×1550×2265 |

| Total Machine Weight (Kg) | 2100 | 2650 | 3200 |