-1-768x1153.png)

Rondella standard

Kingstar series industrial washing extractors are developed and designed by CLM, a leading brand in the laundry industry. We have accumulated over 20 years of technology in the washing equipment industry, aimingtoachieve world-leading technology in industrial washing, andaredetermined to create the personalized industrial washer extractors in the world

Capacità disponibili

Caratteristiche tecniche

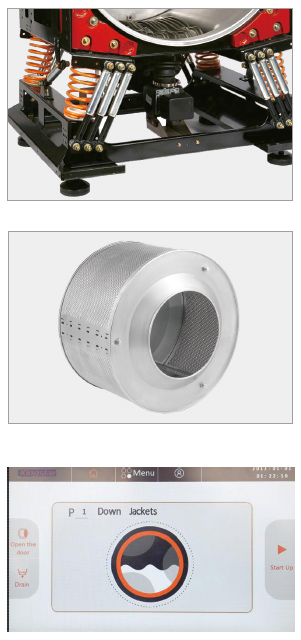

Adcanced Suspension and Shock Absorber System

Equipped with German dampers and ultra-low vibration technology, the suspension system delivers stable, quiet operation on any floor—no foundation required.

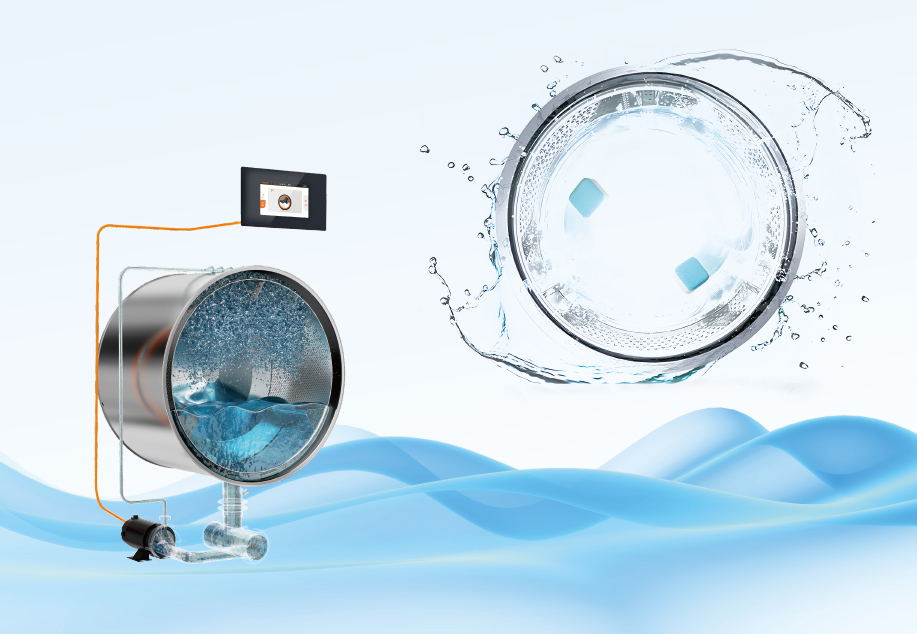

304 Stainless Steel Construction

Il cestello interno, il cilindro esterno e tutte le parti a contatto con l'acqua sono realizzati in acciaio inossidabile 304, per evitare la formazione di ruggine e non compromettere la qualità del lavaggio né il rischio di incidenti.

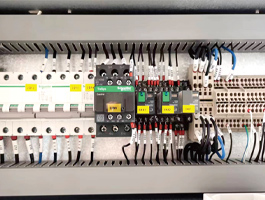

10-inch HD Full LCD Screen

Allows for free programming or one-touch washing, simple and easy to operate.

Electronic Door Lock Design

Optional Automatic Dosing System

Electronic Door Lock Design

Controlled by computer programs, the door can only be opened after the high-speed extraction completely stops, effectively avoiding safety accidents.

Intelligent Weighing Design

Regola automaticamente il volume dell'acqua in base al peso dei vestiti, consentendo un notevole risparmio sui costi di riscaldamento e di detersivo, garantendo al contempo la qualità del lavaggio.

Optional Automatic Dosing System

Open signal interface for any brand of dispenser, allowing precise chemical dosing, reducing waste, saving labor, and ensuring more stable washing quality.

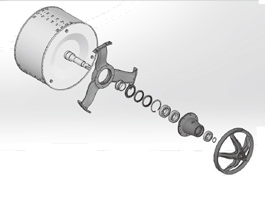

Componenti elettrici importati

Main Transmission Uses Three-Bearing Design

High-Speed Extraction

Designed with a 300G extraction rate, the main motor is custom-made by a listed company, providing excellent performance, high extraction rate, and reduced drying time, effectively saving energy.

Componenti elettrici importati

All electrical components are imported brands, with bearings from USA TWB, contactors from French Schneider, and all wires and plugs being imported brands.

Main Transmission Uses Three-Bearing Design

High strength, ensuring 10 years of maintenance-free operation.

Long-Life Design

The entire machine is designed for a 20-year lifespan, with a 3-year warranty on the whole machine.

Parametri tecnici

| Specificazione | Model SHS-2012 | Model SHS-2015 | Model SHS-2020 | Model SHS-2025 |

|---|---|---|---|---|

-1.png) |

-1.png) |

-1.png) |

-1.png) |

|

| Tensione di esercizio (V/P/Hz) | 380/3/50 | 380/3/50 | 380/3/50 | 380/3/50 |

| Washing Capacity (Kg) | 5~12 | 5~15 | 8~20 | 8~25 |

| Volume del tamburo (L) | 120 | 150 | 200 | 250 |

| Velocità di lavaggio/centrifuga (giri/min) | 30~850 | 30~850 | 30~850 | 30~850 |

| Transmission Power (kW) | 1.5 | 1.5 | 2.2 | 3 |

| Electric Heating Power (kW) | 12 | 12 | 18 | 18 |

| Rumore (db) | ≤70 | ≤70 | ≤70 | ≤70 |

| Fattore di estrazione (G) | 300 | 300 | 300 | 300 |

| Porte di dosaggio automatico (vie) | 9 | 9 | 9 | 9 |

| Pressione del vapore (MPa) | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 |

| Pressione dell'acqua in ingresso (MPa) | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 |

| Diametro del tubo di ingresso (mm) | DN20 | DN20 | DN20 | DN20 |

| Diametro del tubo dell'acqua calda (mm) | DN20 | DN20 | DN20 | DN20 |

| Diametro del tubo di scarico (mm) | Φ76 | Φ76 | Φ76 | Φ76 |

| Diametro del tamburo interno × Profondità (mm) | Φ650×372 | Φ650×465 | Φ750×410 | Φ750×566 |

| Dimensioni complessive (mm) | 890×885×1480 | 890×1070×1480 | 980×1050×1570 | 980×1160×1570 |

| Total Weight (Kg) | 400 | 420 | 480 | 500 |