Industrial Forward Tilting Washer

Leading Technology Pioneering the Era of Intelligent Washing

Kingstar fully automatic washer features a 12.1-inch HD touchscreen design, capable of automatic water addition, pre-wash, main wash, rinsing, and neutralizing processes. It has 30 preset washing programs available and 5 commonly used automatic washing programs.

Available Capacities

Technical Features

01

FRONT TILT

15-Degree Forward-Tilting Design for Easier Discharge

Reducing Worker Labor Intensity

Kingstar forward-tilting fully automatic washer features a 15-degree forward-tilting design, making discharge easier and reducing worker labor intensity.

02

LEADING TECHNOLOGY

Pioneering the Era of Intelligent Washing

12.1-inch HD Touchscreen Design

Kingstar fully automatic washer features a 12.1-inch HD touch screen design, capable of automatic water addition, pre-wash, main wash, rinsing, and neutralizing processes. It has 30 preset washing programs available and 5 commonly used automatic washing programs.

System Of Kingstar Fully Automatic

The intelligent weighing system of Kingstar fully automatic washer automatically weighs each load of laundry, signaling the washing program to adjust water, steam, and detergent levels based on the load, ensuring stable washing quality and saving water, electricity, steam, and detergent costs.

Intelligent Three-color

Kingstar fully automatic washer is equipped with an intelligent three-color status light design, allowing the machine’s operating status to be seen from a distance, including normal washing, washing complete, and fault alarm.

03

RATIONAL STRUCTURE

Advanced Technology Distinctive Features

98%

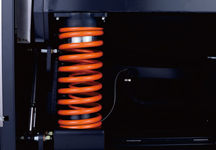

Shock absorption rate

270°

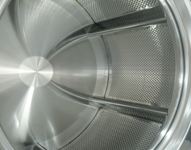

Rolled Edge Opening Design

Triple Shock Absorption Structure

The unique lower suspension shock absorption design of Kingstar fully automatic washer features an inner and outer double-layer base spring + rubber feet shock absorption + damper triple shock absorption structure, achieving ultra-low vibration with a shock absorption rate of up to 98%, eliminating the need for a foundation and allowing use on any floor.

270-degree Rolled Edge Design

The loading port design of Kingstar fully automatic washer features a 270-degree rolled edge design at the junction of the inner drum and outer cylinder, with a smooth surface, high strength, and small gap, effectively preventing damage to clothing.

04

SUPERIOR DEHYDRATION RATE

Energy Saving and Consumption Reduction

400G

Ultra-High Spin Extraction Capability

Kingstar fully automatic washer is designed with a machine strength, transmission system, and high-quality inverter configuration centered around a 400G super dehydration capacity. The superior dehydration rate significantly reduces the moisture content of towels and linens, shortening drying time, increasing daily output, and reducing steam consumption, greatly saving steam costs.

05

SAFETY DESIGN

Ensuring Worry-Free Washing

Extra-large stainless steel loading door

Kingstar fully automatic washer features a large stainless steel loading door, making loading and unloading clothes time-saving and effortless. The electronic door lock is controlled by computer programs, allowing the door to open only after high-speed extraction has completely stopped, effectively avoiding personal safety accidents.

Made Of 304 Stainless Steel

The inner drum, outer cylinder, and all water-contacting parts of Kingstar fully automatic washer are made of 304 stainless steel, ensuring the washer never rusts and preventing washing quality issues due to rust.

The outer drum body tilts backward by 3.5 degrees

The outer cylinder of Kingstar fully automatic washer is tilted 3.5 degrees backward, allowing clothes to be agitated from left to right and also turned from outside to inside, improving cleaning efficiency and effectively avoiding damage to clothes from being pressed at the door gap.

06

BRANDED ACCESSORIES

More stable quality Reduced after-sales costs

Imported Electrical components

Kingstar fully automatic washer uses imported electrical components, including Mitsubishi inverters from Japan, Schneider contactors from France, and all wires, plugs, and bearings are imported brands.

07

PRECISION-PROCESSED TRANSMISSION STRUCTURE

Durable and Long-Lasting

160mm

Largest main shaft diameter

5 years

No need to replace bearing seals

Reliable transmission system

The transmission system of Kingstar fully automatic washer is meticulously designed, with the thickest diameter of the main shaft reaching 160mm. Imported roller bearings and oil seals ensure no need for replacement for 5 years.

One-Piece Die-Cast Belt Pulley

The belt pulley of Kingstar fully automatic washer is made of high-grade aluminum alloy, integrally die-cast, ensuring the assembly accuracy of the main shaft, with excellent rust resistance, corrosion resistance, and shock absorption, making it durable and long-lasting.

Technical Parameters

| Specification | SHS-2100T | SHS-2120T |

|---|---|---|

|

|

|

| Operating Voltage (V/P/Hz) | 380/3/50 | 380/3/50 |

| Washing Capacity (Kg) | 100 | 120 |

| Drum Volume (L) | 1000 | 1200 |

| Spinning Speed (rpm) | 745 | 745 |

| Transmission Power (kW) | 11 | 11 |

| Steam Pressure (MPa) | 0.4-0.6 | 0.4-0.6 |

| Inlet Water Pressure (MPa) | 0.2-0.4 | 0.2-0.4 |

| Noise (db) | ≤70 | ≤70 |

| Dehydration Factor (G) | 400 | 400 |

| Steam Pipe Diameter (mm) | DN25 | DN25 |

| Inlet Pipe Diameter (mm) | DN50 | DN50 |

| Hot Water Pipe Diameter (mm) | DN50 | DN50 |

| Drain Pipe Diameter (mm) | DN100 | DN100 |

| Inner Drum Diameter (mm) | Φ1310 | Φ1310 |

| Inner Drum Depth (mm) | 750 | 950 |

| Front Tilt Angle (°) | 15 | 15 |

| Total Weight (Kg) | 3690 | 3830 |

| Overall Dimensions L×W×H (mm) | 1860×1870×2470 | 1860×2090×2470 |