Professional Washer

Intelligent Washing and Care, Ensures safer washing

Kingstar intelligent washing system developed by professional software engineers and experienced laundry masters from Taiwan, setting optimal washing speeds and stop/rotation ratios for different fabric types to achieve the best washing power without damaging clothes.

Available Capacities

Technical Features

INTELLIGENT WASHING AND CARE

Ensures Safer Washing

-

15 rpm

Minimum rotation speed

-

70+ sets

Customizable washing programs

-

12.1 inches

Full LCD touchscreen

- Kingstar intelligent washing system developed by professional software engineers and experienced laundry masters from Taiwan, setting optimal washing speeds and stop/rotation ratios for different fabric types to achieve the best washing power without damaging clothes.

- Minimum speed of 10 rpm, suitable for high-end fabrics like silk, wool, and cashmere.

- Capable of programming over 70 washing programs, with custom programs transferrable between devices. Features a 12.1-inch full LCD touch screen, simple operation, automatic chemical dosing, and one-touch completion of the entire washing process.

- Personalized settings for each washing program based on fabric characteristics, including main wash speed, high-speed extraction speed, time, and temperature, ensuring garment safety.

- The junction between the inner drum and outer cylinder is designed with rolled edges, with a gap of 4-6mm, smaller than similar products from Europe and the US. The door adopts a convex glass design, keeping clothes away from the loading port to avoid damage from zippers and buttons getting caught.

- The inner drum, outer cylinder, and all water-contacting parts are made of 304 stainless steel, ensuring no rust and no impact on washing quality or risk of accidents.

REFINED INNER DRUM AND SPRINKLING SYSTEM

Cleaner Washing

-

304

Stainless Steel Inner Drum and Outer Cylinder Material

-

3mm

Inner Drum Mesh Hole

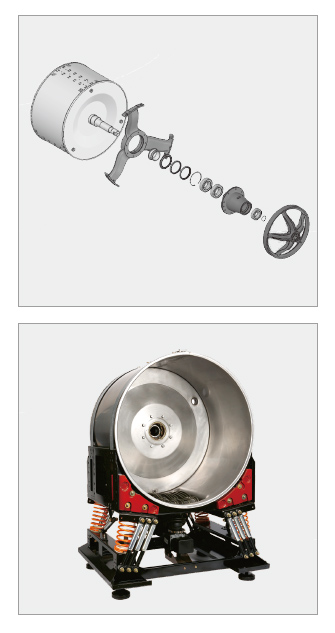

The inner drum and outer cylinder of the Kingstar wet cleaning washer series are made entirely of 304 stainless steel, with a thickness greater than similar machines from Europe and the US. The inner drum is manufactured using mold technology and specialized Italian equipment, resulting in a seamless, beautiful, durable design.

The inner drum mesh adopts a diamond surface design with a 3mm hole diameter, increasing the friction surface of the clothes to effectively avoid damage and enhance the cleanliness of the clothes.

Equipped with a sprinkling system to effectively filter lint and achieve cleaner washing.

INTELLIGENT WEIGHING AND HIGH EXTRACTION FACTOR

Lower Washing Costs

-

400G

G-force Design

The intelligent weighing system adjusts water, chemical, and steam volumes based on the actual weight of the clothes, saving water, electricity, steam, and chemical costs while ensuring stable washing quality.

The extraction factor is designed at 400G, preventing water spots when washing down jackets and significantly reducing drying time, effectively lowering energy costs.

OPTIMIZED DESIGN FOR HIGHER WASHING EFFICIENCY

Higher Washing Efficiency

-

22

Optimized Design Features

The Kingstar wet cleaning washer series has 22 optimized designs compared to standard washers on the market, including automation, washing process, mechanical tumble force, surface friction, liquid detergent, and drainage, resulting in higher washing efficiency and greater value creation.

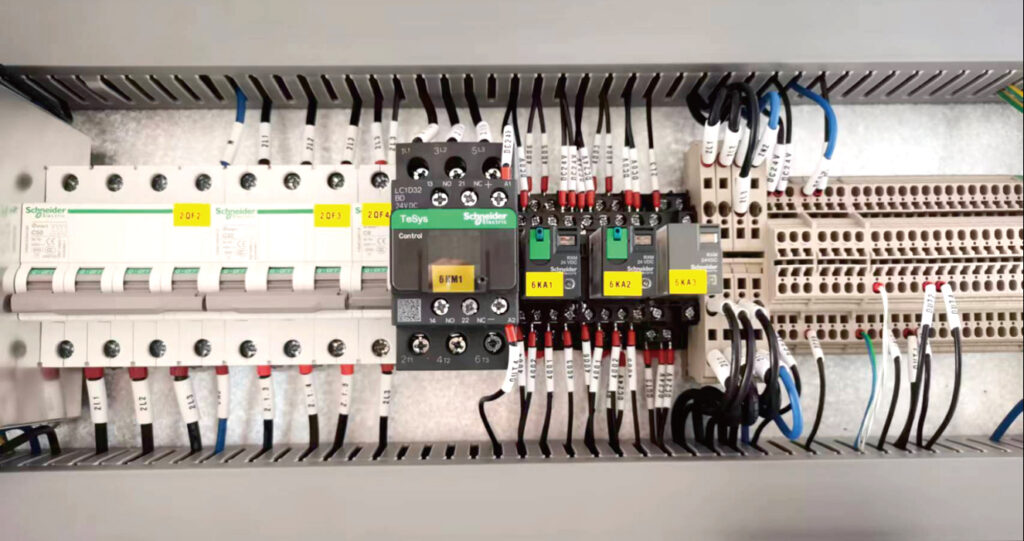

IMPORTED COMPONENTS FOR MORE STABLE QUALITY

Product Stability

The main motor is custom-made by a listed company in China, with bearings from the US TWB, circuit breakers, contactors, and relays from French Schneider, and all wires, plugs, and fasteners being imported brands, ensuring overall machine quality and product stability.

LONG-LIFE DESIGN WITH A 3-YEAR WARRAN

Better Durability

-

5 years

no need to replace bearing seals

-

20 years

lifespan

-

3 years

warranty on the whole machine

- The frame structure uses a weld-free process, ensuring high structural strength and stability, avoiding large stress deformation due to welding.

- The intelligent extraction design ensures low vibration, low noise, and good stability during high-speed extraction, with a long service life.

- The main transmission uses a three-bearing design, with bearings and oil seals from 3 imported brands, ensuring high strength and maintenance-free operation for 5 years years without needing to replace the bearings or oil seals.

- The entire machine is designed for a 20-year lifespan, with a 3-year warranty on the

whole machine.

Technical Parameters

| Specification | Model SHS-2012P | Model SHS-2015P | Model SHS-2020P | Model SHS-2025P |

|---|---|---|---|---|

|

|

|

|

|

| Operating Voltage (V/P/Hz) | 380/3/50 | 380/3/50 | 380/3/50 | 380/3/50 |

| Washing Capacity (Kg) | 5-12 | 5-15 | 8-20 | 8-25 |

| Drum Volume (L) | 120 | 150 | 200 | 250 |

| Washing/Spinning Speed (rpm) | 15-980 | 15-980 | 15-980 | 15-980 |

| Transmission Power (kW) | 1.5 | 1.5 | 1.5 | 3 |

| Electric Heating Power (kW) | 12 | 12 | 18 | 18 |

| Noise (db) | ≤70 | ≤70 | ≤70 | ≤70 |

| Extraction Factor (G) | 400 | 400 | 400 | 400 |

| Automatic Dosing Ports (ways) | 9 | 9 | 9 | 9 |

| Steam Pressure (MPa) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

| Inlet Water Pressure (MPa) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

| Steam Pipe Diameter (mm) | DN15 | DN15 | DN15 | DN15 |

| Inlet Pipe Diameter (mm) | DN20 | DN20 | DN20 | DN20 |

| Hot Water Pipe Diameter (mm) | DN20 | DN20 | DN20 | DN20 |

| Drain Pipe Diameter (mm) | Φ76 | Φ76 | Φ76 | Φ76 |

| Inner Drum Diameter × Depth (mm) | Φ650×372 | Φ650×465 | Φ750×457 | Φ750×566 |

| Overall Dimensions (mm) | 890×885×1480 | 890×1077×1480 | 980×1050×1570 | 980×1160×1570 |

| Weight(Kg) | 400 | 420 | 480 | 500 |